Different Ways to Load Pipe (And How to Secure a Load of Pipe)

Is your transportation partner familiar with how to properly dispatch and load your loads of pipe?

Getting freight from here to there. Shipping pipe should be no different than shipping anything else, right?

Well, not exactly.

When transporting pipe in particular, there are safety concerns and necessary steps to protect the pipe — and your investment.

Understanding different ways to load pipe, as well as how to secure pipe, can help you best choose a transportation partner to ship your pipe and maximize the return on your transportation investment.

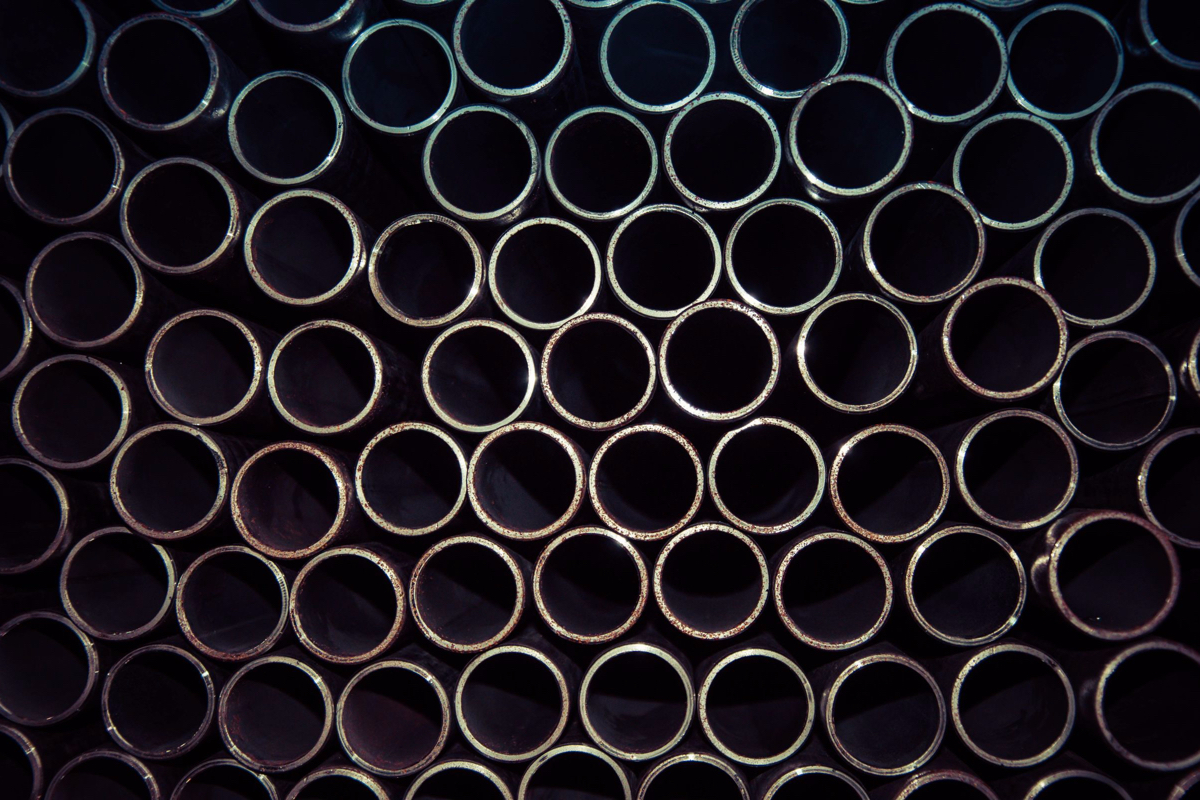

Different ways to load pipe

There are two (2) typical ways that pipes are stacked to load on a trailer:

1. Strip loaded

Used typically for yard-to-yard or yard-to-rail shipment, strip loading is most often considered the preferred method of stacking pipe, because pipe can be loaded and unloaded via forklift and in larger quantities. Strip loading maximizes the pieces of pipe per truck load, considering the size and weight of the pipe.

2. Pyramid loaded

Typically used for yard or warehouse to jobsite transport, pyramid loading provides maneuverability necessary to navigate through obstacles and can accommodate lifting through methods besides a forklift. This flexibility is a must when transporting to a jobsite.

Need help determining how much pipe will fit on a truck? This guide from NASPD can help.

How to Secure a Load of Pipe

Once you’ve decided the best way to load your pipe, it’s time to secure your load. It is important to have your dunnage/lumber on the deck of the trailer ready and pipe stakes/ pipe pins on one side of the load so that you can begin loading.

Check out this short video, which walks you through properly securing a load of pipe to a flatbed trailer.

Safety when loading pipe

Although specifics vary based on the exact size and material of the pipe, as well as the type of flatbed being loaded, there are some common hazards to look for when loading pipe for transport, including:

- Weight of the load lifted.

- Range of the lift.

- Location of the pipe.

- Size and shape of the pipe.

- Number and frequency of lifts performed.

- Proper selection of equipment for the loading and unloading tasks. Pinch points/line-of-fire area.

- Overloaded or improperly loaded (poor weight distribution) trucks/rails/trailers.

- Uneven and/or shifted loads reducing the overall stability of the load/vehicle.

- Missing or damaged strapping/tie-downs.

- Requirement for stanchions on trailers/trucks.

- Potential energy stored in load.

- Means of securement (tie down strap, banding, etc.).

- Proximity of the operation to overhead power lines or other structures. Presence of ice, snow, or other environmental hazards.

- Worker safety when working from an elevated position.

- Proper selection of lifting rigging (chains, slings, straps, vacu-lifts, etc.). Qualified operators must run the lifting equipment.

- Change of ground conditions as it relates to equipment stability.

It can be a bit overwhelming to keep all of those hazards in mind when preparing your shipment, but they are critical to keep people safe, protect your pipe, and it’s worth repeating — protect your investment.

In addition to watching out for the above hazards, be sure to follow these steps:

1. Conduct a visual inspection. Be sure to visually inspect all rigging prior to use to determine if it is suitable for the lifting operations.

2. Be sure you are using the right materials. Verify that stakes/uprights in pockets on trailer edge, chocks on deck, strapping/tie-downs or other similar devices are of sufficient width and padded to prevent damage to or shift of the pipe/cylindrical stock when applicable.

Don’t sweat the small stuff when shipping pipe. Loadstar Transportation can help.

Here at Loadstar, we are flatbed trucking specialists. Tell us what you need and where it needs to go, and we’ll present an efficient, safe solution with trusted drivers and equipment.

We have access to the type of trailer you need, when and where you need it. That includes everything from a 48ft flat, 53 flat, or a 40 ft hotshot trailer. As an asset-based and 3pl provider, we are well positioned to handle your multi-load projects, safely and efficiently.

When you partner with Loadstar, you have one point of contact for sales, dispatch or any accounting or invoicing related questions. We track all your loads and take care of all the details so that you can focus on running your business.

Contact us today to learn more.